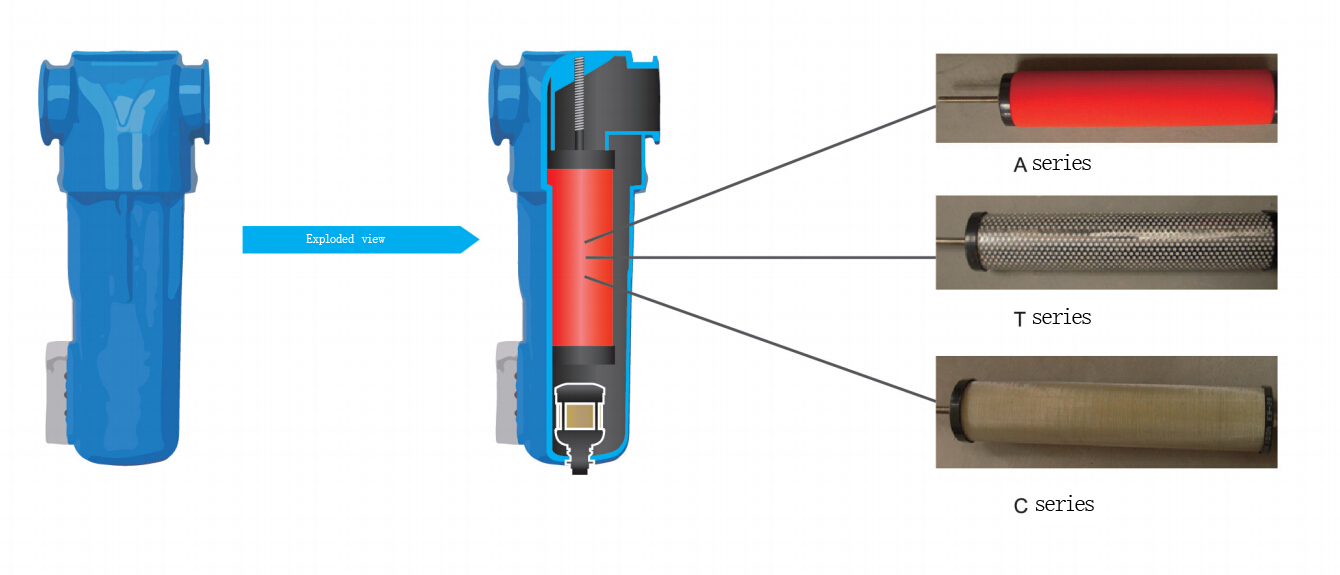

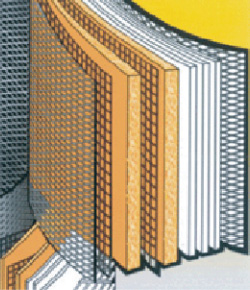

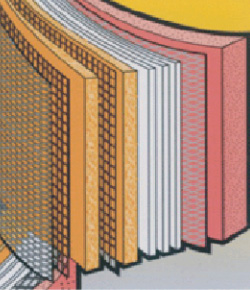

Compressed air filter

Working conditions and design parameters

Working pressure: 16bar (thread interface) 10bar(Flange interface)

Pressure loss: 0.07bar

Processing capacity: 1~400Nmm³/min

Operating temperature range: 1.5~80℃

Replacement parts cycle:6000hours

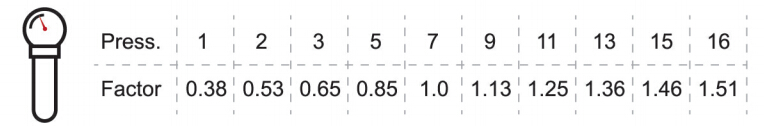

Compressed air filter correction parameters

dd

Intake pressure(bar)